We customize each of our epoxy tables with a wide choice of colors, sizes, textures and shapes to create a truly unique piece that adds personality to any interior.

Unlike other materials, epoxy resin furniture is non-porous, which makes it much easier to clean and maintain. With all the possibilities this type of furniture has to offer, you can create a stunning centerpiece in any room while ensuring it stands up to whatever everyday life throws at it.

Whether you opt for a classic style or something more contemporary, an epoxy resin table is sure to make a lasting impression.

What are the steps involved in making an epoxy resin table?

CHOICE OF WOOD

Step 1

We choose the best wood planks of the chosen species.

SHAPING

Step 2

We validate together the best coloring of the resin according to the wood and your interior.

THE STONE

Step 3

We study together the best choice of base to accompany the table.

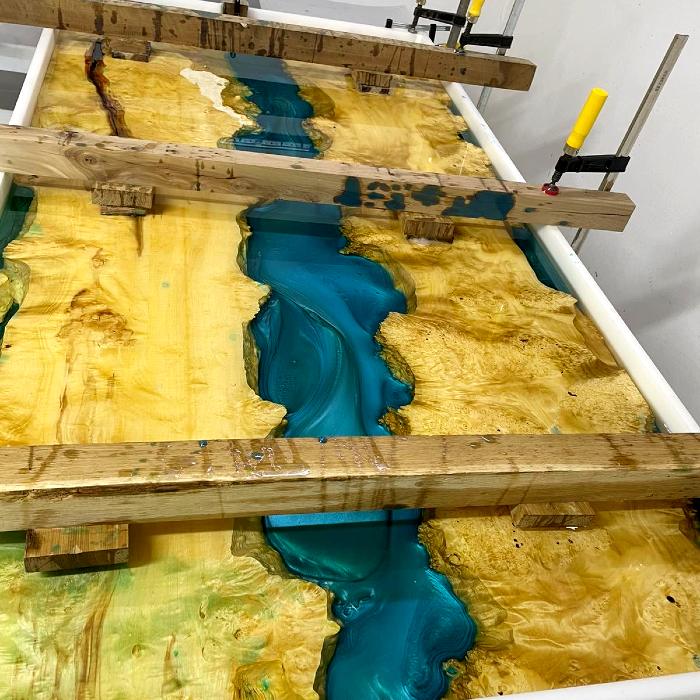

A PHOTO CONTROL BEFORE CASTING THE RESIN AND ESPECIALLY A FOLLOW-UP WITH VISUALS

AND VIDEOS OF THE PROGRESS OF YOUR TABLE

Why are epoxy resin tables so popular?

Today, epoxy river tables are extremely rare and very fashionable. They will enchant you by their beauty and their unique character.

At first glance, it seems that making such a table is quite easy, but in reality it is a complex and precise process.

To make an epoxy resin table requires professional skills as well as noble solid wood, specially treated and dried for 3 to 5 years.

You will find through the visuals how pieces of wood, we manage to sublimate them with resin to give them a breathtaking result.

OUR CUSTOMER TESTIMONIALS:

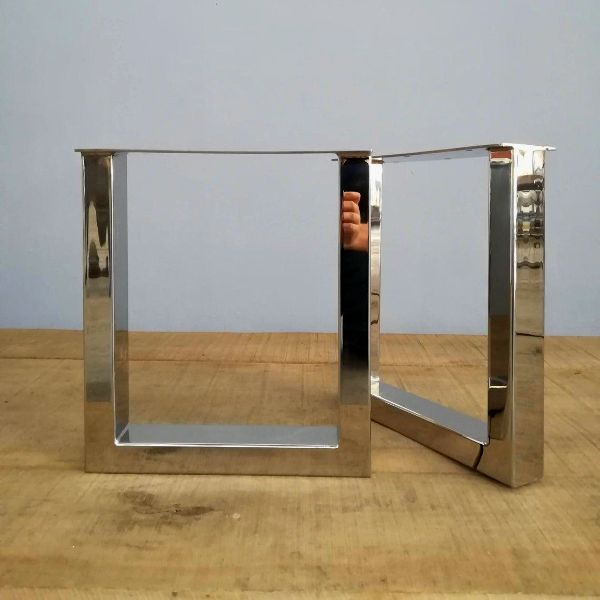

What type of legs to use with our trays?

Black mikado base

White mikado base

Asymmetrical black mikado base

Black V-leg

Gold-plated cylindrical base

Black three-legged base

Silver M base

Gold-plated M base

Legs M black

Black square base

Crossed tube base “Office” style

Square base in shiny stainless steel